Water Utility Modernization

CFW11 drives, PLC500 controls, and Pump Genius automation stabilized pressure zones and cut demand charges.

Download Water Case StudyVersatile General-Purpose VFD for Industrial Applications

The CFW11 is WEG's most versatile variable frequency drive, offering exceptional performance and flexibility for a wide range of industrial applications. With power ratings from 1/2 HP to 1000 HP, built-in PLC functionality, and extensive communication capabilities.

Integrated programmable logic controller functionality eliminates the need for external PLCs in many applications, reducing system costs and complexity.

Specialized pump control algorithms for constant pressure, multipump, and multiplex applications with automatic alternation and energy optimization.

Multiple fieldbus options including Modbus RTU/TCP, DeviceNet, Profibus, EtherNet/IP, and WEG's own WEGnetz protocol.

Advanced vector control with encoder feedback, torque control, and automatic motor tuning for optimal performance and efficiency.

Automatic energy optimization, sleep function, and flying start capability deliver significant energy cost reductions.

Removable HMI with parameter copy function, setup wizards, and comprehensive diagnostic capabilities for quick commissioning.

Dual-port Ethernet modules provide ring architectures, secure diagnostics, and PLC500 integration.

Seamless communication with Siemens PLCs, distributed I/O, and European-standard automation cells.

Legacy modernization is simplified with drop-in network replacements and full parameter access.

Optional IIoT gateways push real-time performance metrics and alarms to historians and cloud platforms.

Large-horsepower drives need coordinated automation. We engineer PLC500 logic, drive parameter sets, and visualization that keep operators informed and protected across distributed assets.

Fiber, copper, and wireless topologies with redundant PLC/drive communications and addressing.

Step-by-step verification for drives, PLCs, and safety circuits with documented pass/fail criteria.

Firmware management, spare parts lists, and operator training tailored to each facility.

From MCC buckets to outdoor walk-in enclosures, Gross Automation packages CFW11 drives with starters, bypasses, isolation transformers, and field wiring ready to drop into plant infrastructure.

One-lines, schematics, conduit schedules, and nameplate engraving documents.

Panel elevations, heat load calculations, and footprint drawings for facility coordination.

Torque logs, parameter exports, and witnessed test results archived for compliance.

Deploy Pump Genius multiplex sequences with automatic alternation, anti-cavitation, and SCADA alarming.

Coordinate regenerative braking, load sharing, and crane anti-sway logic across multiple CFW11 drives.

Integrate BACnet gateways, building automation trend logs, and demand limiting for energy rebates.

Leverage conformal coating, NEMA 4X options, and surge protection for harsh pumping environments.

Use these assets during stakeholder meetings to highlight proven upgrades with CFW11 drives and Gross Automation engineering.

CFW11 drives, PLC500 controls, and Pump Genius automation stabilized pressure zones and cut demand charges.

Download Water Case StudyRegenerative CFW11 packages with PLC500 safety delivered uptime gains and remote diagnostics for mill cranes.

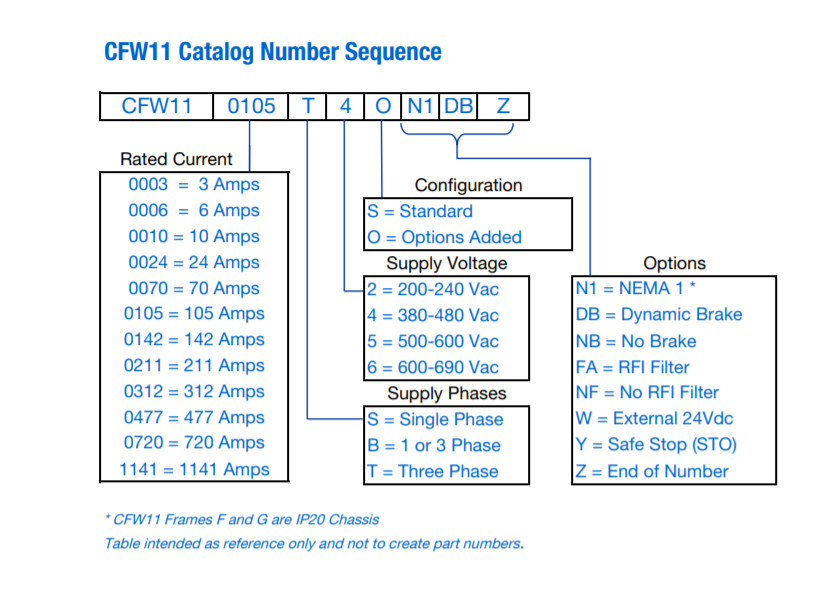

Download Metals Case StudyCFW11 drives follow a specific part numbering system. Our technical team can help you select the correct part number for your application.

Our drive specialists can help you choose the right CFW11 configuration for your specific application requirements.

Get Selection HelpConsider motor horsepower, voltage, duty cycle (heavy-duty vs normal-duty ratings), required control mode (V/Hz, vector, or torque), communication protocol needs, and environmental conditions. Contact Gross Automation for application-specific sizing assistance.

CFW500 drives are compact, installer-friendly units ideal for OEM machinery up to 150 HP. CFW11 drives offer higher power ratings up to 1000 HP, more extensive SoftPLC capabilities, Pump Genius algorithms, and broader communication options for complex industrial applications.

Yes. Most WEG CFW series drives include SoftPLC functionality with IEC 61131-3 programming. The CFW11 and CFW500 series feature extensive logic capabilities that can eliminate the need for external PLCs in many applications.